Urea formaldehyde resin glue is an initial urea-formaldehyde resin which is obtained by polycondensation reaction of urea and formaldehyde as raw materials and has certain viscous properties. When used, it is prepared by adding a hardener or other auxiliary materials. The prepared initial urea-formaldehyde resin is applied to the surface of the wood, and under certain conditions, the resin molecules continue to polycondense and finally form a firm adhesive layer to glue the wood. Urea-formaldehyde resin glue is an initial urea-formaldehyde resin with a certain viscosity obtained by polycondensation reaction of urea-formaldehyde as raw material. It is prepared by adding hardener or other auxiliary materials during use. The prepared initial urea-formaldehyde resin is applied to the wood surface, and under certain conditions, the resin molecules are continuously polycondensed, and finally a firm adhesive layer is formed to bond the wood.

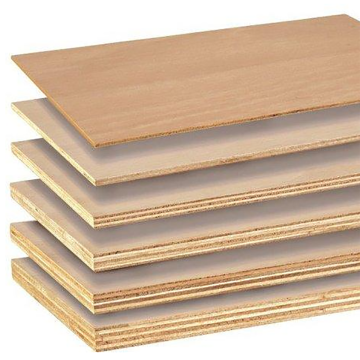

Urea-formaldehyde resin adhesive has high bonding strength, good temperature resistance, water resistance and water resistance. In addition, because the resin itself is transparent or milky white, the prepared particleboard and medium density fiberboard are beautiful in color, and the produced plywood is pollution-free, and its use on wood products does not affect the appearance.

There are many grades of urea-formaldehyde resin adhesives at home and abroad, but urea-formaldehyde resin products mainly have the following three types as glue:

1. Liquid: It can be divided into two types: viscous liquid and foam glue.

Viscous Liquid: A milky liquid resin whose resin content varies with the grade of the product. This resin glue has great instability, and the storage of the resin has a certain time limit, generally three to six months. If the storage time is too long, the resin itself will gradually thicken and gel due to further polycondensation and lose its function.

Foaming urea-formaldehyde glue: before use, add a foaming agent to the undehydrated urea-formaldehyde resin liquid, and mechanically stir the foam to increase the volume of the glue liquid and reduce the weight, so as to achieve the effect of saving the amount of rubber material and reducing the production cost.

2. Powder: It is sprayed by liquid resin spray. This glue has the characteristics of long storage time, convenient use (add appropriate amount of water to prepare glue, or directly glue wet wood with powder), and is convenient for packaging and transportation.

3. Film: a tape film that is coated on paper or dipped in paper to dry.

Of the above types, the most commonly used are urea-formaldehyde adhesives of viscous liquids. In addition, urea-formaldehyde resins can be divided into cold-setting adhesives and thermosetting adhesives according to the curing temperature. Due to its good performance, it is widely used in the production of wood-based panels and the bonding of various wood products. It is an indoor rubber.